permanent magnet

Molded Magnets

Injection Molded Magnets

Magnetic Properties

| Grade | Br | Hcb | Hcj | (BH)max | TW | Tensile streng | 270°Cx5kg Mell Flow Rate | Density | Molding shrikage Coefficient | ||||

| kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | °C | Mpa | G/10 min | g/cm3 | % | - | %/°C | |

| - | - | - | - | - | - | - | - | - | ASTMD-638 | ASTMD-638 | ASTMD-792 | DIC Method | - |

| Ferrite Powder +Binder Nylon6 | |||||||||||||

| *IMF0606 | 185 | - | 127 | - | 231 | - | 6.4 | - | ≤140 | - | - | - | - |

| *IMF0606 | 220 | - | 171 | - | 278 | - | 9.6 | - | ≤140 | 50 | 200 | 3.05 | 0.6 |

| *IMF0606 | 250 | - | 191 | - | 223 | - | 12.4 | - | ≤140 | 60 | 120 | 3.4 | 0.6 |

| *IMF0606 | 260 | - | 195 | - | 255 | - | 13.6 | - | ≤140 | 50 | 100 | 3.45 | 0.6 |

| *IMF0606 | 275 | - | 199 | - | 247 | - | 14.4 | - | ≤140 | 55 | 130 | 3.5 | 0.6 |

| *IMF0606 | 280 | - | 203 | - | 238 | - | 15.6 | - | ≤140 | 54 | 130 | 3.6 | 0.5 |

| *IMF0606 | 290 | - | 207 | - | 250 | - | 16.8 | - | ≤140 | 60 | 110 | 3.65 | 0.5 |

| *IMF0606 | 295 | - | 211 | - | 263 | - | 17.6 | - | ≤140 | 50 | 100 | 3.7 | 0.4 |

| Ferrite Powder +Binder Nylon12 | |||||||||||||

| IMF0212 | 115 | - | 79 | - | 203 | - | 2.4 | - | ≤120 | 40 | 200 | 2.9 | 0.7 |

| IMF1212 | 265 | - | 199 | - | 250 | - | 12.8 | - | ≤120 | 50 | 50 | 3.45 | 0.5 |

| IMF1512 | 280 | - | 195 | - | 250 | - | 15.2 | - | ≤120 | 40 | - | 3.6 | 0.5 |

| IMF1612 | 290 | - | 199 | - | 247 | - | 16.8 | - | ≤120 | 40 | - | 3.65 | 0.5 |

| Hybrid Power +Binder Nylon/PPS | |||||||||||||

| IMH13PPS | 260 | - | 179 | - | 227 | - | 13.2 | - | ≤180(PPS) | 40 | 40 | 3.55 | 0.4 |

| IMH34PPS | 450 | - | 302 | - | 915 | - | 33.6 | - | ≤180(PPS) | - | - | 4.65 | - |

| Injection NdFeB Magnets | |||||||||||||

| IMN-2 | 200-400 | 2.0-4.0 | 120-240 | 1.5-3.0 | 560-720 | 7.0-9.0 | 6.4-24 | 0.8-3.0 | ≤120 | - | - | 3.5-4.0 | - |

| IMN-4 | 400-490 | 4.0-4.9 | 247-310 | 3.1-3.9 | 573-732 | 7.2-9.2 | 28-36 | 3.5-4.5 | ≤120 | - | - | 4.0-5.0 | - |

| IMN-6 | 490-570 | 4.9-5.7 | 312-382 | 3.9-4.8 | 637-796 | 8.0-10.0 | 42-56 | 5.2-7.0 | ≤120 | - | - | 5.0-5.5 | - |

| IMN-8 | 570-630 | 5.7-6.3 | 382-430 | 4.8-5.4 | 676-835 | 8.5-10.5 | 59-67 | 7.4-8.4 | ≤120 | - | - | 5.0-5.5 | - |

| IMN-6H | 480-560 | 4.8-5.6 | 334-398 | 4.2-5.0 | 1035-1353 | 13.0-17.0 | 40-52 | 5.0-6.5 | ≤120 | - | - | 5.0-5.5 | - |

| Injection SmCo Magnets | |||||||||||||

| SMB-6(1:5) | 400 | 4 | 280 | 3.5 | 800 | 10 | 30~50 | 4~6 | ≤120 | - | - | - | - |

| SMB-10(1:5) | 500 | 5 | 320 | 5 | 800 | 10 | 50~65 | 6~8 | ≤120 | - | - | - | - |

| SMB-10(2:17) | 600 | 6 | 360 | 4.5 | 800 | 10 | 65~80 | 8~10 | ≤120 | - | - | - | - |

| SMB-12(2:17) | 700 | 7 | 400 | 5 | 800 | 10 | 80~95 | 10~12 | ≤120 | - | - | - | - |

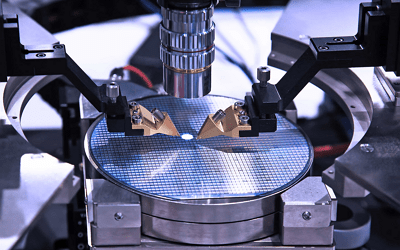

Injection molded magnets utilize a range of magnetic powders, including neodymium-iron-boron (NdFeB), samarium-cobalt (SmCo), and ferrite, as well as thermoplastic resins such as PA6, PA12, and PPS.

Application

The unique characteristics of injection molded magnet products set them apart in many respects. They boast flawless, visually appealing surface finishes with extremely high dimensional accuracy, eliminating the need for subsequent secondary processing. Their complex shaping capabilities extend to micro-geometric forms, offering new dimensions of design freedom. Additionally, these magnets provide consistent performance stability, effectively withstand vibrations, and possess impressive resistance to mechanical shock.

These attributes collectively make injection molded magnets indispensable components in precision motion and sensing applications. Their versatility, coupled with their reliability and performance advantages, has led to widespread adoption in these demanding engineering fields.